Pre-Scale Engineering Discipline: The Hard Truths Behind Scaling a Physical AI Product Part 2

By Dr. Keshav Prasad · Senior Vice President of Product Development and Operations

Once you understand the system-level vision, you need to make it real, and that begins with engineering. This is not about CAD drawings or circuit boards; it is about deeply listening to customers, negotiating what is possible, and building the foundation for a product that can scale. At Dexterity, engineering is where the promise of physical AI starts to take shape, grounded in trade-offs, systems thinking, and hard-won principles of product design.

If manufacturing is the body, and operations is the nervous system, then engineering is the brain of Mech. At Dexterity, every product journey starts with a simple but essential question: What does the customer truly need, and what are they willing to pay for?

We start not with internal targets or spec sheets, but with real-world workflows: What environment will it run in? Who operates it, and how often? What uptime and cycle time make the business case work? How does the customer measure success? These are not abstract questions; they are the backbone of good engineering. Once we understand the customer, we translate that into system-level requirements, defining performance, interfaces, reliability, latency, and safety boundaries. Only then do we break it down into hardware and software specs, for grippers, arms, drivetrain, compute, sensors, diagnostics, and everything else needed to make Mech not just functional, but field-ready.

Product design is not a wishlist. It is a negotiation. We do not just negotiate within Dexterity between software, hardware, and field teams. We negotiate with our customers too, openly and honestly. We ask: What is possible with the current state of technology? What will bend our architecture, and what might break it? What is the real cost of that “just one more” feature, in time, in dollars, in downstream complexity? These conversations are not easy, but they are critical. Our customers do not need magic. They need a roadmap they can trust. This is how we keep Mech real, not hypothetical.

We follow a few hard-won truths that have saved us more than once: The first decisions are the most permanent. A flawed concept will haunt you, no matter how fast you move. Even being first to market will not help if your architecture limits performance or reliability. Good architecture starts with a sound concept. We stress-test ours early, for feasibility, simplicity, extensibility, and long-term risk. A weak concept gets more expensive with every build. You do not get a second chance if your product fails in the field. Reliability and build quality are table stakes, not stretch goals. Get customer traction first. Then optimize cost. Premature cost-cutting leads to fragile designs and painful field failures.

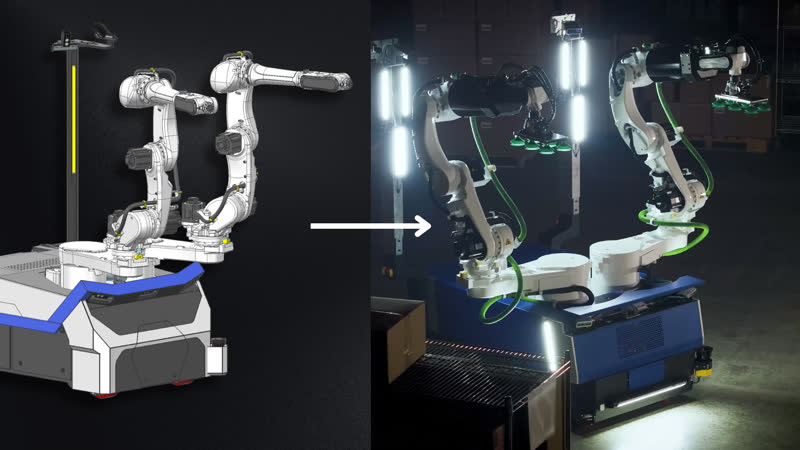

We do not treat Mech as a one-off product. It is the foundation of a platform, and we have designed it accordingly. Our architecture supports: Robotic arms, chassis, compute, vision, powertrain, harnessing, all shared across Dex product lines. Subsystems are designed as swappable, reusable blocks, easily adapted across truck loading, palletization, and parcel handling. We use an Integrate-to-Order approach, pushing customization as late as possible, so we can scale efficiently without sacrificing flexibility.

Building Physical AI is not just about vision. It is about balance, and that is where our engineering team puts its weight. We follow a disciplined Design for X (DfX) framework that ensures we do not just build great robots; we build real products that thrive in the field. Safety is non-negotiable. Operator safety, service safety, system fail-safes: everything starts here. The system must perform. Accurately. Repeatably. Robustly. Performance metrics are not “nice to have”; they mean survival. A product is not real until it balances all competing constraints: manufacturing, certification, ergonomics, service, cost, testability. Balance is where the magic happens, and where most prototypes go to die.

Here is how we apply DfX every day: Design for Assembly, Design for Cost, Design for Ergonomics, Design for Manufacturability, Design for Certification, Design for Reliability, Design for Serviceability, Design for Diagnostics, Design for Test, Design for Transportability, Design for Aesthetics. Whether we are designing a gripper or onboarding a CM, DfX is baked into the process. Because when you design for safety, functionality, and balance, the result is not just a flashy demo; it is a product that lasts.

In a previous startup, we shipped what we thought was a “working prototype” to a customer site. Within days, it failed. The cause? A system that had not been fully characterized for all field environments. We had tested function, not endurance. The cost: weeks of credibility, frantic triage, and damaged trust. Since then, I have carried a rule: You do not ship until you have tested the extremes.

When we started building Mech, we made a conscious choice: Do not treat the field as your lab. Do not treat manufacturing as a handoff. Build with the end in mind. We mapped out everything required to go from prototype to product, and treated each item as core to product success, not “nice to have”: Validation and verification, Component qualification, Reliability growth modeling, Functional safety, Logistics planning, Packaging and shipment, NPI and manufacturing training, Spare parts strategy, Field diagnostics and support, Documentation and certification.

Great engineering sets the direction, but it takes great manufacturing to realize it. All the smart design decisions in the world will not matter if they cannot be built at scale, on time, and with consistency. In the final blog of this series, I will walk through how we approached manufacturing at Dexterity, why we partnered with Sanmina, what it takes to make physical AI real in production, and how we turned the “invisible work” into a competitive advantage.